초임계 질소 발포 기술

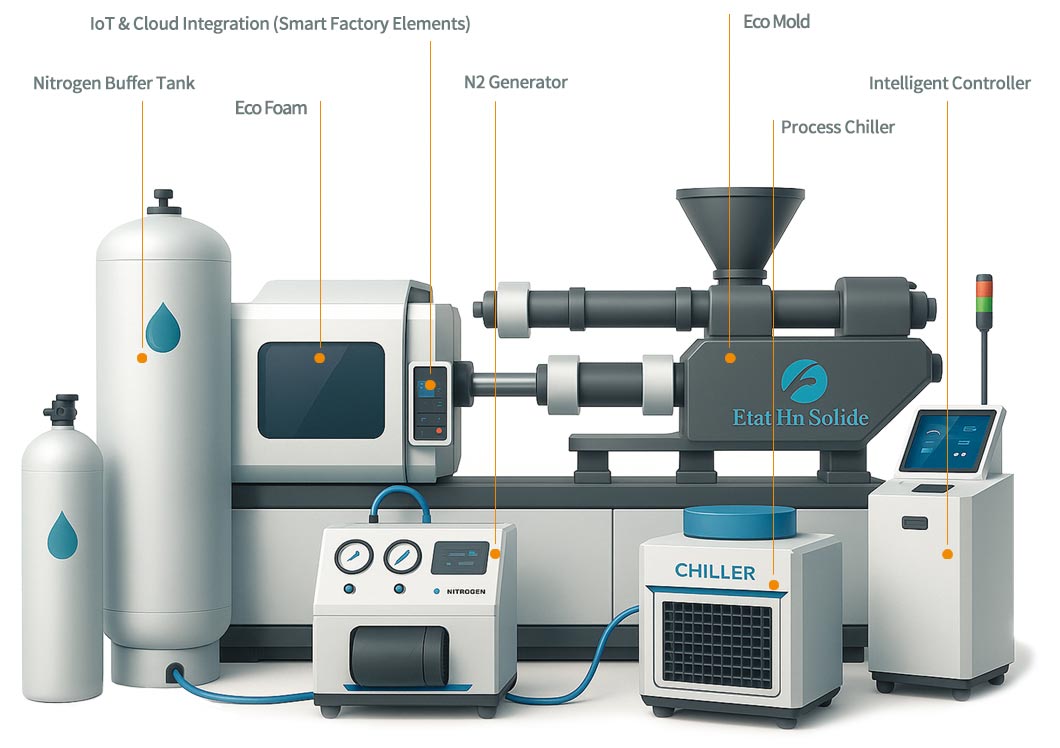

The series includes the EcoFoam System,

EcoMold System, and

Eta One-Cycle Solution,

representing advanced technologies in foaming, molding, and AI-based process control.

These systems have demonstrated up to 40% weight reduction,

enhanced surface quality (high-gloss, paint-free), and

50% energy savings across automotive, appliance, packaging, and industrial applications.

EtaSolid’s injection molding machine integrates next-generation supercritical foaming technology

(EcoFoam) with advanced mold surface control

(EcoMold), forming a unified

ETA Solution platform.

Unlike conventional single-plunger systems, it adopts a

double-plunger (dual injection unit) structure

to achieve precise control and superior foam uniformity.

This configuration allows independent control of injection pressure and gas dosing,

maintaining uniform material density while achieving

up to 40% weight reduction.

Equipped with an in-house developed AI-based control algorithm and

real-time process monitoring sensor network,

the system automatically compensates mold temperature, pressure, and gas distribution,

minimizing quality deviation during mass production.

The surface achieves Class-A gloss without additional painting,

while the internal cell structure maintains high mechanical strength

thanks to precisely controlled supercritical nitrogen expansion.

The system supports both structural and non-structural parts for

automotive, aerospace, drone, and home appliance industries,

and is offered as a complete smart factory package

combining EcoFoam-Enabled Injection System,

EcoMold Tooling,

AI PC Control, and

Smart Chiller Integration.

Through this, EtaSolid presents an intelligent lightweight plastic solution that surpasses the limitations of conventional foam injection molding.

| Category | Item | Unit | Specification |

|---|---|---|---|

| Injection Unit | Screw Diameter | mm | 55 / 65 |

| Injection Pressure | kg/cm² | 1253 | |

| Injection Capacity | cm³ | 863 | |

| Injection Weight (PS) | g | 621 | |

| Injection Rate | cm³/sec | 301 | |

| Screw Stroke | mm | 260 | |

| Injection Speed | mm/sec | 91 | |

| Plasticizing Capacity (PS) | kg/h | 133 | |

| Screw Revolution | rpm | 200 | |

| Screw Peripheral Speed | m/min | 35 | |

| Clamping Unit | Clamping Force | ton | 220 |

| Tie-Bar Distance | mm | 560 × 560 | |

| Platen Size | mm | 820 × 820 | |

| Open Stroke |